BY RICHARD STEVENSON, EDITOR, CS MAGAZINE

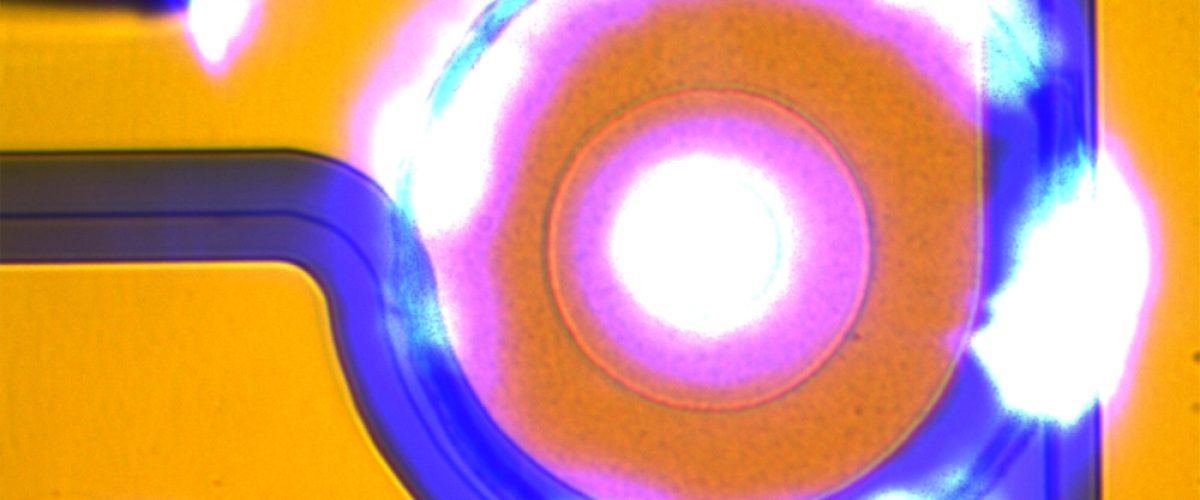

Over the last few years the GaN VCSEL has come on in leaps and bounds, enjoying substantial gains in lifetime, efficiency and output power. Thanks to all this great progress, blue and green VCSELs are now standing on the brink of commercialisation.

Taking this next step is far from easy, but the chances are now better than ever, thanks to a significant breakthrough from a little-known a start-up that’s located far away from the centre of the action. While much of the early running has come from big names in Japan, such as Nichia, Sony and Stanley Electric, the driver of GaN VCSEL commercialisation is Ganvix of Wilmington, DE.

What distinguishes this trailblazer from its peers is the approach it takes to form the bottom mirror of the VCSEL. Rather than making a distributed Bragg reflector (DBR) from interlacing layers of GaN and a ternary nitride – a pairing that is slow to grow, and, due to a lack of lattice-matching, introduces light-quenching defects into the active region – Ganvix combines conventional layers of GaN with porous variants, produced by electrochemical etching.

Company CEO John Fijol told Compound Semiconductor that the start-up is planning to sample VCSELs to its customers in early 2023, targeting output powers of 5 mW or more.